*

This

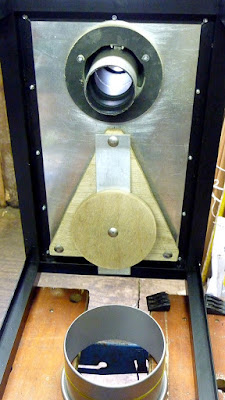

image shows a potential layout for a mirror support plate resting and

clamped tightly onto a removable block or packing piece. I did not want

to make an endless series of mirror support plates until I finally

reached the correct slope angle to provide initial tilt. The reason

being the rather short but stiff springs I now intend to use for the

mirror collimation plates. The mirror tilt wants to be close to ideal

before the collimation wing nuts are even touched.

This

image shows a potential layout for a mirror support plate resting and

clamped tightly onto a removable block or packing piece. I did not want

to make an endless series of mirror support plates until I finally

reached the correct slope angle to provide initial tilt. The reason

being the rather short but stiff springs I now intend to use for the

mirror collimation plates. The mirror tilt wants to be close to ideal

before the collimation wing nuts are even touched.A slot in the mirror support plate will allow a clamping bolt to pass through the mirror backing disk to provide sliding vertical adjustment. This will ensure that each mirror is centered on the optical axis of the objective. The tilt and depth of the mirror supporting shell will cause the center of the mirror's reflective front surface to rise relative to its support. The slot will allow easy adjustment to bring it back on axis if necessary.

A packing block will ensure stability rather than relying on further springs for mirror tilt adjustment. Each new spring in a support system increases the risk of vibration or even an unwanted shift in collimation. Which may be due to a knock when being handled or placed on the mounting. A folded refractor needs to have a stable optical support system. The OTA must avoid repeating collimation on every occasion it is brought out and placed on the mounting ready for observation.

Though it doesn't look it, the collimation triangle for the 1st, folding mirror, is now parallel with the framework and backplate. Short, stiff coil springs have been slipped over the 6mm SS coach bolts. The square shanks, under the domed heads, prevent screw rotation when the collimation wing nuts are tightened.

I am persevering with the plywood triangle for the moment to avoid wasting aluminium. It is better to prove a system works before committing to expensive or no longer obtainable materials. If you are like me, a new idea pops up out of nowhere just as the last hole is drilled. Then you wonder why you never thought of it before.

The backplate is already full of unwanted holes from the first mirror cell adjustment screws. An ATM adviser suggested finer collimation adjustment might be needed. The greatly expanded triangle was my response to that need.

A trial strip of aluminium has been bent and fitted to the top collimation screw for location.

A trial strip of aluminium has been bent and fitted to the top collimation screw for location.I hung the flat shaving mirror onto the strip and sighted through the objective aperture. This took a couple of bending trials before I was able to see the reflected, 2nd mirror target centralized on the inside of the OTA shoulder.

The bottom of the tilt strip will have a bolt through a packing piece to lock the strip solidly to the triangle. The tilt angle is much smaller than I might had guessed. This is probably due to the angle being effectively doubled by the reflection.

The packing piece has yet to be fitted and bolted into place. The coach bolt will be reversed in the slot once the tilt strip is finished.

Here the plywood mirror backing disk is bolted to the tilt strip to give a sense of scale. The shell which will hold the 125mm, 5" 1st, folding mirror fits over the backing disk and will probably be screwed to it. Dowel spacers will support the back of the mirror blank at the correct height in its supporting shell.

I was advised on a forum to wrap the edges of the mirror blanks in Teflon tape. This would give room for thermal expansion and contraction of the shell and also protect the mirror surfaces from the shells' rims.

The 5" mirror shell sits in the foreground. I didn't fit it for the photograph so that the backing disk arrangement could be better seen.

The old weather continues to hamper progress in the unheated shed as my nose drips and my hands ache with the cold when I touch cold metal. Perhaps it is just as well that I am progressing so slowly. It gives me plenty of time to think about the next step. Just writing about it seems to concentrate my focus on the best option. And gives my adviser plenty of time to suggest a solution based on his own, recently completed 8" folded refractor project.

Replacing the present plywood collimation triangle, in aluminum, would allow the top and bottom of the sheet to be bent. These surfaces could match the required angles of the collimation screws. The screws really ought to be perpendicular to the framework back plate as well as the triangular plate. Skewed screws have no real stability.

The triangle would provide the necessary mirror pre-tilt without the need for the present, additional strip. As cutting the triangle requires rather a large sheet of aluminium I am saving my last, remaining stock for the moment. Once I have proved the optical layout I can continue with metal rather than the plywood patterns.

As my helpful ATM adviser has pointed out there is a problem of access to the sliding mirror height, clamping screw. This could be more easily accessed through a hatch in the backplate. Once the OTA is enclosed in a shroud or covered in panels access within the framework would become far more difficult. The non-structural, rear hatch could save some weight. Since the hatch cover need not be of the same heavy [4mm] aluminium material.

Much is made of the desirability of careful sealing in any refractor but I am still undecided. A folded refractor has multiple beams rather than the usual, single, straight shot from objective to eyepiece. Sealing a refractor is not usually very successful anyway without extreme care. The focuser and objective collimation system are usually wide open to air currents even if the "tube" itself is fully sealed. Naturally I shall experiment with closure to see if it improves image steadiness. Fortunately the prevailing wind usually carries body thermals away from the OTA when pointing south. The 'straight' refractor also gains from having the incoming light path raised high above the ground thermals. Whether the reduction in ground clearance in a folded refractor really matters is still wide open to speculation. Only hands-on experience will provide the necessary proof.

This entire project started as a desire for a longer focus, better corrected refractor than my 6" f:8 Celestron. The resulting OTA proved too unwieldy and heavy to manage safely or easily. The folded refractor was my response to these problems.

Click on any image for an enlargement.

*