*

A Birch plywood OTA "box" with glued, light baffle boards makes a lot of

sense for a compact folded refractor. The plywood is inherently stiff and the baffle

boards will eliminate inward or outward bending of all the other boards.

Plywood is very easily cut compared with aluminium or any other metal. There is a long history of plywood construction where great strength and stiffness are required. Aircraft, boats and cars have all used stressed skin plywood constructions for over a century. The dynamic loads on these lightweight constructions absolutely dwarf anything a telescope is ever likely to meet. Though that is not an excuse to make the structure flimsy.

It just requires that OUR telescope tube uses best construction practice. It must be furnished with a number of incompressible baffle boards to resist skin flexure. Since the telescope needs light baffles anyway, the dual purpose of light blocking and adding strength can be safely met and should be encouraged. The loads in the structure must be spread as evenly as possible throughout. Which is where the skin comes into play. This will strongly resist stretching or compression but it has much lower resistance to bending.

The usual ATM arrangement of using heavy "planks" or thick plywood, adds considerable weight. Relying only on its considerable bulk to stiffen the structure. Which inevitably means it has to be strong enough to support its own [added] weight. Not an efficient use of materials where lightness can reduce the OTA's moment arm. Allowing smaller and cheaper mountings to be used. Not to mention making the telescope much lighter and safer to carry between its storage and the mounting.

Anything which comes between the amateur astronomer and using his telescope is a mental hurdle. One to be overcome every time the telescope could be put into use. Weight adds mental inertia to resist going out to observe on a whim. The best telescope is not the biggest, nor the best, but the one which gets used most often. How do we allow a big telescope to be more user-friendly? By reducing its weight and making it much easier to handle.

Skinned, cellular, aerospace materials, cardboard packaging and even flush house doors all use the skin effect. Which spreads the loads over a large area by the use of a mass of incompressible cells. The materials used can be very thin and even quite weak in themselves. Flush doors often use a cardboard honeycomb of small cells. Gluing the plywood facings onto the cells provides the necessary resistance to bending and compression. Aerospace honeycomb structures are incredibly strong and light despite using paper thin [or thinner] materials in its entire structure. The absence of thick materials allows air to fill the now empty spaces and air has no discernible weight. Bubble wrap would have similar properties if it were glued between suitably stiff skins. We all know how cardboard packaging uses the skin and cell effect to carry the world's goods safely around the globe. Yet it is constructed of thin but relatively weak [paper] materials glued between similar skins. While the common cardboard carpet or concrete form tube are also made of paper but have to be made massively thick and heavy to resist applied loads.

A

very experienced ATM contact has pointed out we live in a wet and cold

Northerly climate. So wood and plywood are far more sensible than metal OTA

constructions. Metal is very prone to condensation, dewing and frost.

With the attendant risk of water dripping onto internally mounted

mirror surfaces. We are used to seeing metal OTAs and probably admiring their

neat and tidy cosmetic appearance. However, anyone who has used such an OTA will attest to the heavy moisture load they seem to attract like a

magnet. My habit of parking my refractors on their dewshields for

compact storage, even in unheated accommodation, has usually resulted in water marking of the back of the

objective lens.

Cardboard, plywood and battens do not

promote condensation due to their low thermal capacity and insulating

qualities. Such materials have a much lower tendency to radiate to the

cold night sky. [Itself a black body absorber.] Exposed metal can actually drop below the local air

temperature due to such radiation causing "super-cooling." As we all

know, thermal differentials are what drive convection currents in the

telescope's own light path. It might be instructional to mount two identical refractors

side by side. With one objective mounted in a typical metal tube and the other

in a plywood tube. Will they show equal thermal effects on the image?

The downside of Birch plywood is that it is rather dense. The

finished OTA, using typical construction methods, is very likely to be heavier than an all-aluminium construction. However, the folded refractor is so compact, compared with a long, straight OTA, it should

still be more easily managed via suitable "drawer" handles. The compact,

stable, boxy shape also lends itself far better to being moved about on

a suitable trolley than any 7-8' long, straight tubed OTA.

A compact, plywood,

telescope tube could use 3 dimensional, cellular construction rather than simple baffles. It

would become inherently stiffer and all the materials could become considerably thinner.

The design really needs to incorporate longitudinal internal structures to

stiffen the "innards." The stressed skin fuselages of aircraft use stringers over plywood formers. [Or baffles in our case.]

A compact folded OTA could be made usefully lighter by using thinner skins supported by thinner cellular construction. Not only would there be thinner baffles and more of them, but their own resistance to flexure would be increased by adding longitudinal structure. These could also be thin, glued plywood braces between baffles or even glued dowels or battens. Though the latter tend to get quite heavy, rather quickly, due to their use of solid material. A sheet of anything reasonably rigid tends to be very strong in its own plane. You could say it enjoys a myriad of triangulation over its entire surface. The trick is to use its inherent 2D stiffness by not allowing it to bend in the third dimension.

One still has to ensure that the light path is kept completely clear and extra weight is not added unnecessarily. Support for the heavy objective in its cell requires local strength. Though there is really no need for a massive counter-cell, type of tube adapter for a compact box. The objective cell's tubular rear extension and collimation screws must still be adequately supported. An objective board, made from a thick, cellular plywood sandwich, is perfectly suited to this task.

The objective board must then have its loads efficiently carried into the OTA box structure without flexure. Applying the typical, extra layers of thick plywood, to spread the loads, just makes the OTA even more nose heavy. Without necessarily spreading the loads further than the limit of their own extent. So a lightweight, cellular structure is called for to support the sandwich objective board. The loads from a lightweight, plywood sandwich must be carried back into the entire box to be evenly distributed via fully 3-dimensional baffling, or cells. They must be arranged in the horizontal, vertical and longitudinal orientations. All skinned over with thin plywood for stiffness.

It must not be forgotten that two layers of ply weigh the same as a single layer of twice the thickness. To reduce weight they must be separated and fixed to an indeformable, lightweight matrix. Then the ply skins themselves can be thinned to match the required stiffness and local resistance to compression.[ie.Impact denting.] The stiffness rises as the square of a structure's depth, or thickness. Which is why joists, studs and rafters are always placed on edge to the applied loads. They are then tied together to resist twisting out of their strongest plane.

One could almost imagine sculpting a fully 3D cellular material by cutting away only the light path but leaving everything else behind. Imagine firing a huge laser pulse into the objective aperture to burn away only the cellular structure where the laser light hits. The objective lens would focus the heat into its natural light cone. The lightness, strength and stiffness of the remaining cellular structure would be phenomenal! It is this idealized structure one must try to emulate to add more air at the expense of unwanted solid material. Though grazing incidence of the light must be avoided. Baffles with any reasonable thickness will often add their own grazing incidence. So thin metal baffles should be applied where the highest contrast is desired.

An alternative to adding baffles is to use an inherently stiff but lightweight material like rigid, closed cell,

extruded insulation foam. NOT the common, polystyrene, bead foam which has rather low strength and poor local compressibility. Lightweight, insulating materials could be skinned with very thin ply to achieve great stiffness without added much weight. Though the foam is never as light as "thin air" itself of course.

The only danger might be an internal fire if such a telescope is used for solar observation via a Herschel wedge. Such methods focus the entire sun's heat right through the telescope structure before reducing it to a safe level just before the eyepiece. Often with the addition of ND filtration to further reduce the brightness. The heat having already been reflected away by the prism in the solar wedge.

I am not talking here about so called "solar filters" supplied with small, cheap telescopes to fit over the eyepiece. These are exceedingly dangerous and should never, ever, be used. Better, by far, to obtain some commercial solar foil filter material from Baader. Which is extremely safe provided it is built onto a structure to place securely in front of the objective. Since the solar foil reflects 99.99% of the sun's heat and light NO heat enters the telescope objective to reach the vulnerable user's eye.

An objective support board could be built from dense foam and thin plywood. The risk of fire being almost nil at the "blunt" end of the light path. The weight of the objective could be easily carried into the objective board by its own cylindrical rear extension. The collimation screws would still need local load distribution to avoid flexure with changing telescope orientation. No point in building a very stiff structure if the heavy objective lens is then allowed to sag away from its supporting board via the collimation screws. Or cause local distortion which would alter collimation as the telescope was moved around on its mounting.

*

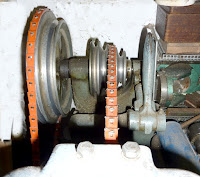

I have taken more images with the lathe headstock partially dismantled. I also wanted to be sure I hadn't forgotten anything since I changed the belts back in January. Now some nine months ago.

I have taken more images with the lathe headstock partially dismantled. I also wanted to be sure I hadn't forgotten anything since I changed the belts back in January. Now some nine months ago. The next image shows the felt oiler for the front, plain headstock bearing. The lower end of the felt sits in a reservoir of oil filled when each of the knurled plugs is removed.

The next image shows the felt oiler for the front, plain headstock bearing. The lower end of the felt sits in a reservoir of oil filled when each of the knurled plugs is removed. The lower end of back gear layshaft pin is exposed by rotating the back gear knob completely. [as shown] This tapered pin must be tapped out from the underside of its normal position to free the back gear shaft. I like to use a small riveting punch with a spherical hollow in the tip to avoid mushrooming the tapered pin. There is no need for a big hammer nor any force. If the pin won't come out easily then check you aren't trying to drive it further in from the wrong end.

The lower end of back gear layshaft pin is exposed by rotating the back gear knob completely. [as shown] This tapered pin must be tapped out from the underside of its normal position to free the back gear shaft. I like to use a small riveting punch with a spherical hollow in the tip to avoid mushrooming the tapered pin. There is no need for a big hammer nor any force. If the pin won't come out easily then check you aren't trying to drive it further in from the wrong end. Remember that the threaded locking collar must also be slipped over the tip of the shaft just before it passes the tumbler gears. The tumbler gears can be removed but it is much easier to leave them in place to avoid extra and unnecessary work. The white washer is PTFE low friction plastic. It goes behind the collar against the headstock casting.

Remember that the threaded locking collar must also be slipped over the tip of the shaft just before it passes the tumbler gears. The tumbler gears can be removed but it is much easier to leave them in place to avoid extra and unnecessary work. The white washer is PTFE low friction plastic. It goes behind the collar against the headstock casting.