*

I have posted these rather poor flash images to show a belt clearance problem with the headstock casting since changing to Nu-T-link 'A' belts. It is completely impossible to change gear without parting the belt, re-threading it onto another pulley pair and then rejoining it.

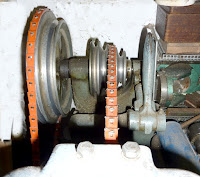

I have posted these rather poor flash images to show a belt clearance problem with the headstock casting since changing to Nu-T-link 'A' belts. It is completely impossible to change gear without parting the belt, re-threading it onto another pulley pair and then rejoining it.The view from the front shows close but just acceptable clearance.

The rear view shows a thicker shelf in the bottom of the casting below the pulleys. [Arrowed]

I have repeatedly promised myself that I would repaint the lathe at some point. This "roundtoit" has lasted for nearly 30 years! The cleaning has gone downhill too over the past two decades. Normally nobody else would ever see it.

The motor's two speed pulleys x four pulley layshaft offers eight gears plus back gear. The large, cast handle on the right releases the belt tension. Changing the belt from one pulley pair to another is entirely manual but normally quick and easy. A turnbuckle sets belt tension.

The older "B" round riveted black linked belting is also unsuitable for the 'Sabel.' Being undersized, noisy and very prone to slippage despite nominal 'A' specification. I had quite forgotten that the higher speeds were possible so severe was the slippage as the rivets bottomed in the pulley grooves.

Overview of headstock. The Nu-T-Link belting is so bulky it will not move between the four, headstock pulleys. This is mostly due to the over-sized belt dimensions plus the projecting riveting striking the casting below the pulleys.

The Smart & Brown "Sabel" offers 8 speeds on the pulleys but has no gearbox. Plus back gear of course. The reversible lead screw provides reversible apron/carriage and cross slide feeds. A full set of change gears provides different feeds and thread pitches. The sable uses split, plain bearings with a ball bearing linear thrust bearing.

Closer view of over-sized Nu-T-Link belting on the 'A' sized headstock pulleys.

The large gears are for the back gear drive to the headstock. A pull-out button disengages the belt drive to the pulleys to avoid clashing between two, very different driving speeds. A large indexed knob at the far left of the headstock engages back gear.

Expensive box of 5 meters of Nu-T-Link belting.

It clearly states 'A' size and 13mm but the Nu-T-Link is actually 14.5mm wide at the tops of the links. The depth over the rivets is 15.5mm! 'A' Spec is 1/2" [12.5mm] x only 8-9mm deep. A very expensive mistake!

I have now ordered a 13mm 'A' x 1325mm belt online from a local car spares outlet. The same outlet which claimed they couldn't help me because they don't know the dimensions of their V-belts! This, despite having dozens of sizes available and all sold by their precise dimensions. Downside with a simple belt is having to completely strip and rebuild the headstock including the back gear. Removing the layshaft is relatively easy. That said, a modern V-belt belt should last for years with reasonable care.

The 'toothed' V-belt arrived next day and it took me only half an hour to fit including some cleaning. The racket coming from the NuTLink belting on the motor pulleys had me quickly reverting to a simple V-belt. I now have no idea why I ever bothered with this expensive and noisy alternative belting. It might make some sense in a commercial environment, where costly dismantling or downtime must be avoided. Elsewhere the 'humble' V-belt is very obviously superior. It is difficult to photograph the lathe due to the narrow space between it and the opposite wall. The overhanging layshaft and steel cabinet add to the problem. Seeing these images jolted me out of my laziness and I gave the painted parts of the machine a spray with water based, engine cleaner and wiped it all down.

Click on any image for an enlargement.

*

2 comments:

Hi Chris,

I have bought a Sabel as my first lathe.

No belts were fitted. I have bought belts to fit. The motor belt is no problem but I can't work out how to get the back gear and main spindles out to fit the new drive belt.

Can you help?

I could undo stuff willy nilly but don't want springs, pins and bearing rollers etc falling out all over.

Thanks

John

Hi John

It's much easier than you would believe.

I can't add images to comments so I'll have to post advice with supporting images on the blog.

No doubt somebody else will post advice on Yahoo.

The blog is easiest for me and I have far more control.

I have two images ready but just need another of the locking ring on the left end of the headstock shaft.

Check the blog for updates over the next half hour in the original S&B Sabel belt post. 30/1/2016.

Good luck

Chris

Post a Comment