*

Friday 21st 23-38F. -5+4C. Overcast. The shutters now work effortlessly with cords or fingers pulling or pushing near the top of the ribs. I can live with that.Here is a rough sketch of the rope layout for closing the shutters. Shutter closure pulleys are attached to the dome zenith board. They have to be spaced apart and the ropes crossed, just to be able to close the shutters fully and efficiently. The lower ends of the two ropes could form a closed loop to avoid duplication of effort.

Meanwhile, the shutter opening ropes need a sunken pulley or eye bolt in each of the upper slit ribs. Otherwise the shutter ribs will strike the protrusion where they meet the slit ribs. Sash window style, fully enclosed pulleys are available from boating and yachting sources.

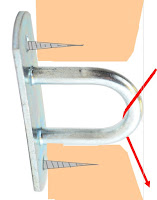

Or, a stainless steel padlock hasp could be fixed to the back of the slit rib. To protrude through a suitably beveled, rectangular hole. The rope should pass freely enough around the loop of the hasp to work effortlessly. Without any protrusion from the rib face.

Hasps could easily replace the pulleys on the zenith board and take up less room. Friction should remain low enough not to hinder shutter movement. It should be possible to carry the ropes down the slit rubs. Where the ropes can be most easily managed from the observatory floor. Perhaps with a little, manual help to keep the lower shutters in step.

I still have to anchor the bottoms of the slit ribs to the base ring. They are currently resting on packing blocks. With a stud [long threaded rod] spanning the bottom of the observation slit to maintain accurate rib spacing.

Considerable trimming of the slit ribs was required to clear the lower, shutter bogies. One problem is leaving enough space for [storm] hold downs. To clear just above the base ring as the dome turns. Which makes bases of the slit ribs even more narrow. Precisely where they should join the base ring. A long, angle [shelf?] bracket may be necessary.I may have to make filler panels for the cutouts from plywood. Then laminate more ply over the outside to reinforce these butt joints. Titebond III wood glue isn't rated for setting in winter cold. So this will have to wait.

As mentioned above, the shutter ribs close flat against the slit ribs in both shutter open and closed positions. So a large arc has to remain clear between them to avoid causing unwanted gaps. This sets severe limits on what is physically possible.

Perhaps I could/should re-fix the lower bogies to the shutter ribs with the shutters closed. Presently I am fixing the brackets with the shutters wide open for easier access to the brackets. This is resulting in slight bowing of the meeting shutter ribs when closed. I might as well try and get it right. As previously mentioned [repeatedly] the shutters greatly exaggerate errors in the level of their support.

*

No comments:

Post a Comment